The highest range audio equipment can be appreciated only when you let it spread its wings and play music in all spectrum of acoustical details. This can be achieved by placing all components onto specifically designed rack-type support.

Base solutions guarantee acoustically and electrically clean conditions for electronic audio devices and turntables. We design them with use of thoroughly tested technologies and materials, thanks to our engineers’ long term experience and research on issues of vibration and resonance. Our rack-type supports help achieve high-end reality of sound in case of any audio system, regardless the price.

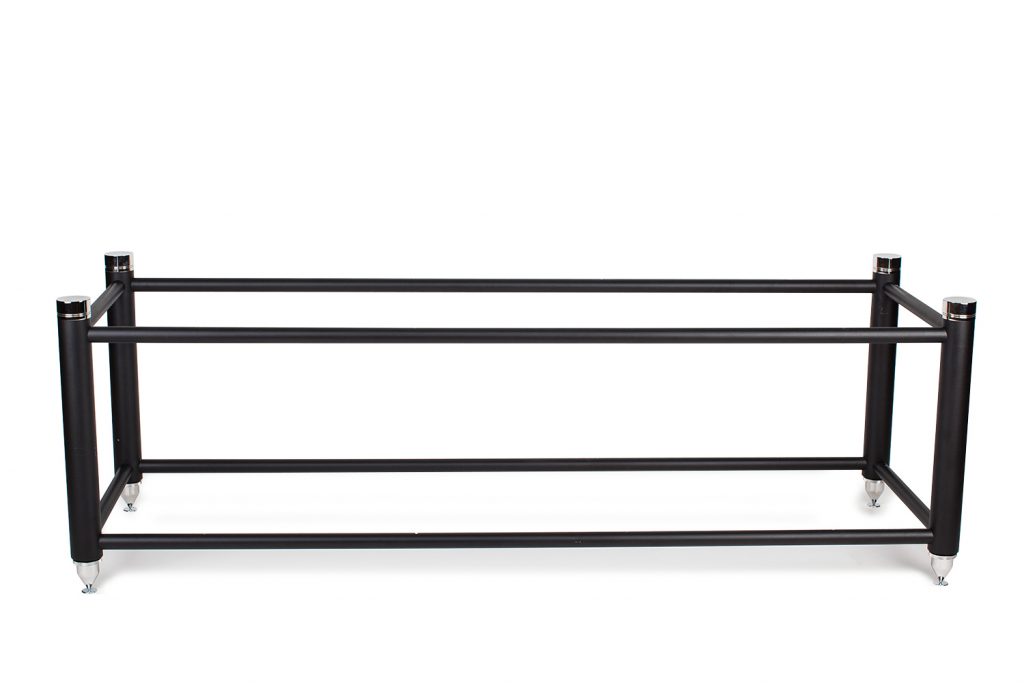

Base rack supports are designed to fulfil very complicated task: protection from external vibrations (especially generated by loudspeakers) as well as eliminating micro-vibrations caused by electronic devices (i.e. power supply transformers)

Key features:

- Big mass load for stable support of audio devices as well as inertia used for natural resonance damping

- Several levels of minimizing parasite vibrations: fully isolated tabletop, welded chassis filled with damper as well as full separation from the floor

- Simple construction principles and versatile design

- The palette of many wooden finishes and colours of chassis

- No limits for customized size and shape available on special order